Plumbing systems - the quiet veins of our buildings, almost invisibly providing an essential service inside our homes, offices and industries. Interestingly, in the world of plumbing with various materials being used to build pipes, PPR pipe (Polypropylene Random Copolymer) has proved itself as an affordable yet strong and flexible material for the job. Specialized factories produce top-grade PPR pipes and fittings, leading the way in this change with their spirits of excellence and continuous innovation. How these factories are changing the game for plumbing systems: Quality Control Efficiency Demanding conditions Eco-friendliness This article dives deep into this world.

A revolutionary step for plumbing systems

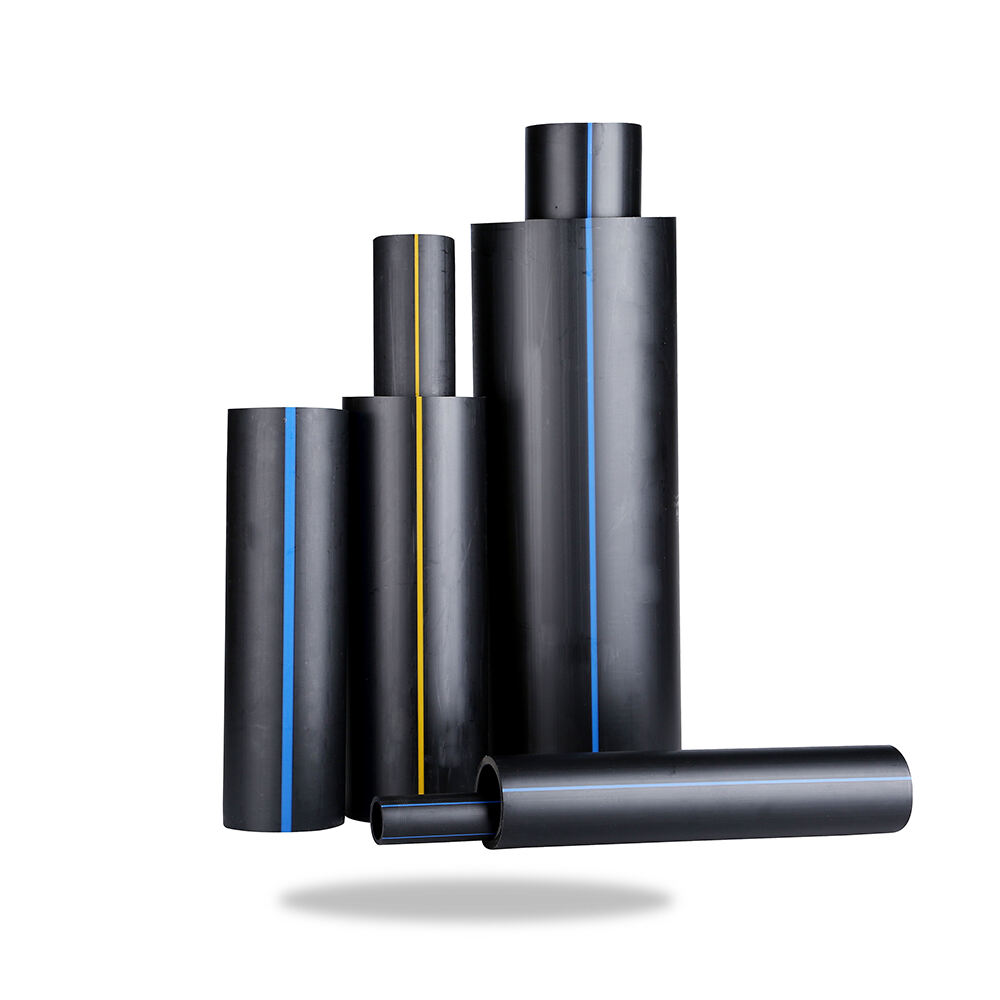

PPR Pipes and Fittings PPR Pipe is groundbreaking advancement in plumbing and offers a far ancient way to solve within the metal or PVC (polypropylene plastic)for cold & warm water duct for commercial and residential pprs piping system moulded pipe with this material Is part of growing experience. Because they are resistant to corrosion, can withstand high temperatures and have low thermal conductivity, these characteristics make them suitable for disparate applications in everything from clean water supply to heating systems. These factories are professionally designed with the latest equipments and experienced engineers producing PPR products that can elegantly fir into new constructions as well as retrofitting projects. In doing this, they ensure that the entire industry moves towards more reliable, long-lasting plumbing solutions which results in reduced upkeep costs and overall system performance.

The Importance of QC

For a sector where leaks can cause substantial harm and health hazards, having good quality standards is vital. Leading PPR pipe and fitting factories make the faucets with looking to tough international standards like ISO 9001 & NSF/ANSI, where each part running through their manufacturing system fulfills a set of toughest marks. This includes extensive pressure, impact and chemical compatible testing. The quality control process also consists of thorough examinations throughout different stages such as during raw material procurement to the final processing/packaging stage. In so doing, these factories maintain that their PPR products not only provide better than expected performance but also trust and confidence in plumbing systems all over the world.

Increasing Efficiency of Plumbing with PPR Fittings

Proper plumbing is something that many people take for granted until it comes time to have the system repaired. Professional Factory produced PPR fittings are high quality and premium connectors,its highly durable construction comes from its precise design of dimensions which help with easy installation leaks legs prevention. Fusion welding is amongst some of the advanced jointing techniques available that provide a continuous system without additional sealants to reduce leak burglars and enhance performance. The inner surfaces of PPR pipes are smooth, thereby reducing friction and providing improved flow rates as well as energy savings in pumping systems. Creating holistic plumbing systems designs in concert with the precinct-level water treatment and management processes enables them to both operate more efficiently, saving resources up front while helping reduce ongoing operating costs over time.

Advantages of Using Superior PPR Pipes in High Stress Areas

The high-quality PPR pipe has great difficulties in the environment of conventional materials. The fact that it is chemically resistant to a myriad of chemicals (even those often present in wastewater) also lends itself well for industrial applications. This means that their capability to preserve structural integrity in freezing-cold or near boiling-point temperatures provides a worry-free and continuous service even for the most extreme climates. The compound is also ultraviolent (UV) resistant, fortifying durability in the face of sunlight to withstand outdoor installations. In this case, PPR pipes from professional factories are adaptive and long-lasting in extreme conditions such as freezing winters (in the far north) or scorching summers(in arid areas).

Sustainable PPR Plumbing Systems Production

The nature of sustainability has shifted from something that brands can choose to adopt, over the years, into a fundamental element in today's manufacturing landscape. Top PPR pipe and fitting manufacturers follow eco-friendly procedures in their service functions which include:- Being a naturally recyclable material, PPR is typically recycled using closed-loop recycling systems at these factories to prevent additional waste and save resources. There are also efforts to save energy and use renewable resources so as not to degrade the carbon footprint. In addition, the long service life and low maintenance requirement of a PPR system can ultimately improve sustainability by eliminating more frequent replacements and associated waste generation which naturally occurs throughout its operational lifecycle. These factories exhibit a dedication to green manufacturing principles, following global movements of promoting eco-friendly practices in every step of production.

To sum it up, professional PPR pipe and fitting manufacturers do a lot to better plumbing systems in terms of functionality, durability as well as sustainability. Their emphasis on integrity, creative engineering,continent adversity and world-class green behavior is changing the plumbing industry by raising performance expectations. We need these factories to be our allies as we construct smarter and more responsible infrastructures.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

MT

MT

FA

FA

AF

AF

MS

MS

GA

GA

CY

CY

IS

IS

AZ

AZ

LA

LA

MN

MN

UZ

UZ

KY

KY