Parametro del prodotto:

Il tubo HDPE per l'acqua è un tipo di tubo plastico flessibile utilizzato per sistemi di fornitura e scarico idrico municipale, sistemi di condotte per il trattamento dell'acqua, sistemi di fornitura e scarico idrico industriale, sistemi di irrigazione rurale o agricola ecc., realizzato in polietilene ad alta densità termoplastica (PE100, PE4710), materiale vergine alimentare al 100% importato da Borealis, non tossico, ecologico e sicuro per il trasferimento di acqua potabile, la sua eccellente flessibilità permette che il tubo PE possa essere arrotolato per un installazione senza scavare fosse, congiunzione a saldatura a freddo. La dimensione massima raggiunta è di 1200mm.

ALTA TENACITÀ

L'allungamento a rottura del tubo HDPE per acqua ZHSU supera il 500%, con forte capacità di adattamento alle irregolarità

del fondamento del tubo, con eccellente capacità antisismica.

NON TOSSECO E SALUTARE

Il materiale della tubazione in HDPE è privo di tossine, ecologico e sicuro, non vengono aggiunti additivi a base di metalli pesanti, si utilizza un materiale vergine di polietilene di grado alimentare per produrre tubi in HDPE per l'acqua, sono sicuri per il trasferimento di acqua potabile.

Eccellente flessibilità

Un'eccellente flessibilità permette che i tubi in PE possano essere arrotolati per rendere l'installazione senza scavo più sicura, fornendo tubi in HDPE con lunghezza elevata per evitare un gran numero di giunzioni e accessori, aumentando l'efficacia economica.

GIUNTA SENZA PERDITE

I tubi in HDPE possono essere uniti tramite saldatura a freddo o saldatura elettrica, la resistenza della giunzione è superiore al corpo del tubo, con resistenza alla pressione dell'urto idraulico, migliorando notevolmente la sicurezza e affidabilità dell'acquedotto.

Resistenza alla corrosione chimica

Il tubo in HDPE può resistere a varie forme di corrosione chimica, le sostanze chimiche nel suolo non causano degradazione del tubo in HDPE, il polietilene è un isolante elettrico, non marcisce e non arrugginisce, inoltre non promuove la crescita di alghe e batteri.

Specifiche

Materiale: Polietilene ad alta densità PE100/ PE4710 con colore nero

Dimensione: DN20mm ~ DN1200mm

Pressione : PN16/SDR11 ~ PN6/SDR26

Lunghezza : 4 metri / pezzo, 3 metri / pezzo , 5.8 metri / pezzo o 100 metri a bobina

Norma : ISO 4427, DIN 8074/75, GB/T13663-2000

Unione : tubi HDPE uniti mediante saldatura a freddo

| Dimensioni (MM) | PN16 | PN12.5 | PN10 | PN8 | ||||

| Spessore (mm) | Peso (kg/metro) | Spessore (mm) | Peso (kg/metro) | Spessore (mm) | Peso (kg/metro) | Spessore (mm) | Peso (kg/metro) | |

| 20 | 2.3 | 0.135 | ||||||

| 25 | 2.3 | 0.173 | ||||||

| 32 | 3 | 0.289 | 2.4 | 0.237 | ||||

| 40 | 3.7 | 0.446 | 3 | 0.364 | ||||

| 50 | 4.6 | 0.693 | 3.7 | 0.553 | 3 | 0.455 | ||

| 63 | 5.8 | 1.051 | 4.7 | 0.868 | 4 | 0.759 | ||

| 75 | 6.8 | 1.469 | 5.6 | 1.231 | 4.5 | 1.005 | ||

| 90 | 8.2 | 2.124 | 6.7 | 1.767 | 5.4 | 1.447 | 4.3 | 1.167 |

| 110 | 10 | 3.167 | 8.1 | 2.614 | 6.6 | 2.161 | 5.3 | 1.757 |

| 125 | 11.4 | 4.101 | 9.2 | 3.374 | 7.4 | 2.756 | 6 | 2.261 |

| 140 | 12.7 | 5.12 | 10.3 | 4.23 | 8.3 | 3.461 | 6.7 | 2.828 |

| 160 | 14.6 | 6.722 | 11.8 | 5.538 | 9.5 | 4.527 | 7.7 | 3.714 |

| 180 | 16.4 | 8.496 | 13.3 | 7.021 | 10.7 | 5.736 | 8.6 | 4.668 |

| 200 | 18.2 | 10.478 | 14.7 | 8.626 | 11.9 | 7.088 | 9.6 | 5.788 |

| 225 | 20.5 | 13.275 | 16.6 | 10.955 | 13.4 | 8.979 | 10.8 | 7.326 |

| 250 | 22.7 | 16.339 | 18.4 | 13.494 | 14.8 | 11.023 | 11.9 | 8.972 |

| 280 | 25.4 | 20.478 | 20.6 | 16.921 | 16.6 | 13.846 | 13.4 | 11.313 |

| 315 | 28.6 | 25.938 | 23.2 | 21.437 | 18.7 | 17.546 | 15 | 14.25 |

| 355 | 32.2 | 32.914 | 26.1 | 27.183 | 21.1 | 22.31 | 16.9 | 18.094 |

| 400 | 36.3 | 41.807 | 29.4 | 34.502 | 23.7 | 28.241 | 19.1 | 23.038 |

| 450 | 40.9 | 52.985 | 33.1 | 43.698 | 26.7 | 35.79 | 21.5 | 29.173 |

| 500 | 45.4 | 65.356 | 36.8 | 53.978 | 29.7 | 44.231 | 23.9 | 36.032 |

| 560 | 50.8 | 81.912 | 41.2 | 67.685 | 33.2 | 55.384 | 26.7 | 45.09 |

| 630 | 109.6 | 378.5 | 46.3 | 85.579 | 37.4 | 70.183 | 30 | 56.999 |

| 710 | 42.1 | 89.041 | 33.9 | 72.579 | ||||

| 800 | 47.4 | 112.964 | 38.1 | 91.922 | ||||

| 900 | 42.9 | 116.436 | ||||||

| 1000 | 59.3 | 176.646 | 47.7 | 151.6 | ||||

| 1200 | 67.9 | 243.9 | 57.2 | 206.997 | ||||

APPLICAZIONE

1: Fornitura idrica municipale, condotte principali per acqua, fogne principali, irrigazione rurale,

2: Alimentare, industria chimica

3: Sostituzione di tubi in cemento, ghisa e acciaio

4: Irrigazione di aree verdi, irrigazione agricola

5: Altre applicazioni come ingegneria elettrica, telecomunicazioni, allevamenti marini ecc

TEST E ISPEZIONE

| Test | Unità | Condizioni di prova | Indice | ||

| Tasso di allungamento | % | ≥ 350 | |||

| Reversione Longitudinale | % | 110℃ | ≤ 3 | ||

| Tempo di Induzione dell'Ossidazione | min | 200°C | ≥ 20 | ||

| Pressione Idrostatica (PE100) | Mpa | 20℃ | 100 ore | Stress 12.4Mpa | Nessuna crepa, nessuna perdita |

| 80℃ | 165h | Sforzo 5,5 Mpa | |||

| 80℃ | 1000h | Sforzo 5,0 Mpa | |||

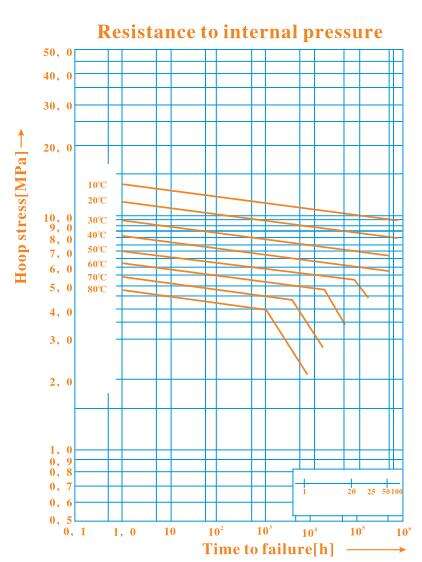

PRESTAZIONE A PRESSIONE IDROSTATICA

CONNESSIONE A FUSIONE A TESTA DI TUBI IN HDPE

Il sistema di tubazioni sotto pressione in HDPE utilizza la fusione a testa per le grandi dimensioni e la fusione a inserimento per le piccole dimensioni.

La fusione a testa utilizza una macchina per saldare riscaldando entrambe le estremità del tubo (la temperatura è 210 + - 10℃) fino a quando l'estremità del tubo si fonde, quindi si deve aderire rapidamente all'estremità del tubo in HDPE mantenendo una certa pressione. Dopo il raffreddamento, tutte le procedure sono completate. La tabella seguente fornisce un riferimento per le procedure di saldatura.

| Spessore del muro (mm) | TECNOLOGIA | |||

| Prima: Preliscaldamento | Secondo: Fusione | Terzo: Interruttore | Quarto: Connessione | |

| Pressione di pre-riscaldamento: 0.15Mpa | Pressione: 0.01Mpa | Massimo:Interruttore | Pressione di saldatura: 0.15Mpa | |

| Temperatura di pre-riscaldamento: 210℃ | Temperatura di pre-riscaldamento: 210℃ | Tempo di Permesso (s) | Tempo di Raffreddamento (s) | |

| Pre-riscaldamento sovrapposizione alta | Tempo di Riscaldamento (s) | |||

| 2-3.9 | 0.5 | 30-40 | 4 | 4-5 |

| 4.3-6.9 | 0.5 | 40 a 70 | 5 | 6-10 |

| 7.0-11.4 | 1 | 70-120 | 6 | 10-16 |

| 12.2-18.2 | 1 | 120-170 | 8 | 17-24 |

| 20.1-25.5 | 1.5 | 170-210 | 10 | 25-32 |

| 28.3-32.3 | 1.5 | 210-250 | 12 | 33-40 |